Lean Six Sigma Yellow Belt Certification Photo Diary at Coca-Cola

[vc_row css=”.vc_custom_1422341624235{margin: 30px 0px !important;padding: 30px 40px 20px !important;background-color: #ffffff !important;border: 1px solid #eeeeee !important;}” row_type=”row” use_row_as_full_screen_section=”no” type=”full_width” text_align=”left” background_image_as_pattern=”without_pattern”][vc_column width=”1/1″][vc_row_inner][vc_column_inner width=”1/3″][vc_column_text]

[/vc_column_text][/vc_column_inner][vc_column_inner width=”2/3″][vc_column_text]

[/vc_column_text][/vc_column_inner][vc_column_inner width=”2/3″][vc_column_text]

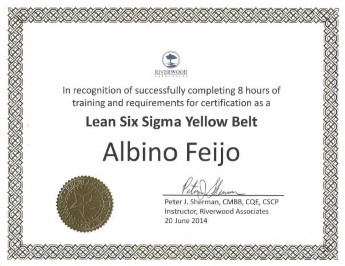

Lean Six Sigma Yellow Belt Certification

Training Day

JUNE 20, 2014

A full day of discovery-driven, interactive training using the DMAIC framework. Extensive use of using hands-on team exercises to reinforce key concepts and tools.

A full day of discovery-driven, interactive training using the DMAIC framework. Extensive use of using hands-on team exercises to reinforce key concepts and tools.

Learning, Doing, Sharing, and Leading[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_separator type=”normal” position=”center” color=”#cccccc” thickness=”1px” up=”20px” down=”20px”][vc_column_text]

Participants

42 participants from 27 organizations participate.[/vc_column_text][vc_row_inner][vc_column_inner width=”1/3″][vc_column_text]-Alpha Technologies

-Altair Advanced Industries

-APL Logistics

-Bacardi USA

-Bake One

-Bimbo Bakeries USA

-Brown Logistics Services

-Coca-Cola Company

-Docufree Corp.[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/3″][vc_column_text]-Eaton Corp.

-Emory University

-Fineline Tech

-DS Waters of America

-Graphic Packaging

-King & Spalding LLP

-MacDermid Printing Solutions

-MSC Industrial Supply Co.

-Preferred Personnel Solutions[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/3″][vc_column_text]-Rehrig Pacific

-Softrol Systems Inc.

-Talent Stream Inc.

-Textile Group Inc.

-The Clorox Company

-Thompson Hine LLP

-Walk Thru the Bible Ministries

-Whirlpool – Embraco

-YKK-USA, Inc.[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_separator type=”normal” position=”center” color=”#cccccc” thickness=”1px” up=”20px” down=”20px”][/vc_column][/vc_row][vc_row][vc_column width=”1/1″][vc_column_text]

Training Day at Coca-Cola

[/vc_column_text][TS_VCSC_Timeline_Container timeline_order=”asc” timeline_sort=”true” timeline_break=”600″ timeline_lazy=”true” timeline_count=”5″ timeline_trigger=”scroll” timeline_load=”Load More” timeline_title_color=”#7c7979″ timeline_description_align=”center” timeline_description_color=”#7c7979″ margin_top=”0″ margin_bottom=”0″][TS_VCSC_Timeline_Single full_width=”true” featured_media=”image” featured_image=”15483″ attribute_alt_value=”Our Class” lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Our Class” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]42 participants across a variety of industries including Manufacturing, Food & Beverage, Logistics, Technology, Higher Education, Legal, Accounting, Staffing, and Non-Profit.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Break color_background=”#ededed” title_text=”Process Mapping” title_align=”center” title_color=”#7c7979″ content_align=”center” content_color=”#7c7979″][TS_VCSC_Timeline_Single full_width=”false” featured_media=”slider” featured_slider=”15485,15486″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Discovery” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Teams hard at work mapping the Current State LSS Yellow Belt Process (Promotion-to-Certification)[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15487″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Team 3 discovers its easier to just layout the process on the table!

Dyrc McLeod – Textile Group; Gilson Horstmann – Whirlpool Embraco; Kent Kise – DS Services.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15488″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Understanding the Problem” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Brian Kenny and Edgardo Beltran of YKK-USA trying to understand the problem.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15489″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Readouts” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Edgardo and Brian, YKK-USA, giving the readout.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15490″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Learning and Doing” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Team 5 discovers it helps to huddle together very close![/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15491″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Sharing and Leading” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Sergio Duviella and Ivan Mino of Bank One have a difference of opinion![/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15492″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Show Me The Muda” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Erna Wilkerson, Emory University, shows us where the muda is![/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15493″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Process Mapping Readouts” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]The ladies from Team 1 give a readout: Erna, Lois, Michelle, Tamara and Priscilla[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15494″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Team 2 hard at work and running out of space![/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15495″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Albino Feijo, Coca-Cola, gives the readout to the class.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”slider” featured_slider=”15496,15497″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”ts-awesome-lightbulb-o” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]John Watkins of Thompson Hine LLP, identifying a Kaizen Starburst opportunity.

John is proud to present his findings![/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Break color_background=”#ededed” title_text=”Lunch Presentation” title_align=”center” title_color=”#7c7979″ content_align=”center” content_color=”#7c7979″][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15498″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]During lunch, Albino Feijo – Director of Process Excellence at The Coca-Cola Company, gives a presentation on Coca-Cola’s Operational Excellence Program.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15499″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Terrence Spencer asks Albino a question about training all 700,000 employees in the Coca-Cola System!

Albino responds, “It’s a long-term process.”[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Break color_background=”#ededed” title_text=”Root Cause Analysis” title_align=”center” title_color=”#7c7979″ content_align=”center” content_color=”#7c7979″][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15500″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_text=”Fishbone Diagram” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Gilson Horstmann, Whirlpool-Embraco, explains the Fishbone Diagram[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15501″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Team 3 presents their readout of root causes (Joseph, Dyrc, Gilson, and Kent)[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15502″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Shannon Stamey, President of Preferred Personnel Services, gets to the root cause of why so few organizations effectively operationalize Lean Six Sigma training.

“You need leadership to get engaged!”[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Break color_background=”#ededed” title_text=”Improve” title_align=”center” title_color=”#7c7979″ content_align=”center” content_color=”#7c7979″][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15503″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Ray Todd, Altair Advanced Industries, showing us how to think “outside the box” during the Improve stage.[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Break color_background=”#ededed” title_text=”Certification Process” title_align=”center” title_color=”#7c7979″ content_align=”center” content_color=”#7c7979″][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15504″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]At the end of the day, the class takes the Lean Six Sigma Yellow Belt Certification exam to demonstrate knowledge and proficiency of key principles, techniques and tools. Minimum score of 80% passing grade.

[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15508″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Tired, but still smiling . Overall, it was a great day of learning, doing, sharing, and leading! We are very proud of the highly collaborative team effort between The Coca-Cola Company, APICS Atlanta and Riverwood Associates.

[/TS_VCSC_Timeline_Single][TS_VCSC_Timeline_Single full_width=”false” featured_media=”image” featured_image=”15508″ lightbox_featured=”true” page_rtl=”false” featured_youtube_related=”false” featured_youtube_play=”false” featured_dailymotion_play=”false” featured_vimeo_play=”false” featured_media_height=”height: 100%;” featured_media_width=”100″ featured_media_align=”center” title_align=”center” title_color=”#7c7979″ icon=”transparent” icon_color=”#7c7979″ tooltip_css=”false” tooltip_position=”ts-simptip-position-top” button_align=”center” button_width=”100″ button_type=”square” button_square=”ts-button-3d” button_rounded=”ts-button-3d ts-button-rounded” button_pill=”ts-button-3d ts-button-pill” button_circle=”ts-button-3d ts-button-circle” button_size=”ts-button-normal” button_wrapper=”false” button_text=”Read More” button_change=”false” button_color=”#666666″ button_font=”18″ lightbox_group=”true” lightbox_effect=”random” lightbox_backlight=”auto” lightbox_backlight_color=”#ffffff”]Tired, but still smiling . Overall, it was a great day of learning, doing, sharing, and leading! We are very proud of the highly collaborative team effort between The Coca-Cola Company, APICS Atlanta and Riverwood Associates.

Scott Luton, Albino Feijo, Peter Sherman[/TS_VCSC_Timeline_Single][/TS_VCSC_Timeline_Container][vc_column_text]

Course Survey and Results

[/vc_column_text][vc_row_inner][vc_column_inner width=”2/3″][vc_column_text]Instructor[/vc_column_text][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Knowledge of Subject 4.9 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.9″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Style of Teaching 4.8 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.8″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Enthusiasm 4.9 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.9″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”10px” down=”10px”][vc_column_text]Class[/vc_column_text][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Content 4.8 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.8″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Material/Handouts 4.8 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.8″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Pace 4.6 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.6″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”10px” down=”10px”][vc_column_text]General[/vc_column_text][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Pace 4.7 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.7″ icon_color=”#cccccc” icon_active_color=”#002f6a”][vc_separator type=”transparent” position=”center” thickness=”1px” up=”2px” down=”2px”][vc_column_text]Overall 4.9 out of 5.0

[/vc_column_text][progress_bar_icon type=”normal” icon=”fa-star” size=”small” icons_number=”5″ active_number=”4.9″ icon_color=”#cccccc” icon_active_color=”#002f6a”][/vc_column_inner][vc_column_inner width=”1/3″][vc_column_text]

Would you recommend course to others?

37 out of 38 said “Yes”. 1 – NA.

Comments:

“Was very well run and informative.”

“Great content, energy and real-world examples of Lean Six Sigma in practice.”

“Outstanding curriculum and presentation.”

“Peter enjoyed teaching the class. Interacted well with the class.”

“Great delivery and knowledge. Fabulous!”[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row]